- Pre-Sales :027-82634167

- After-Sales:027-82829786

289 Huangpu Street, Jiang 'an District, Wuhan, China

Phone

027-82829785

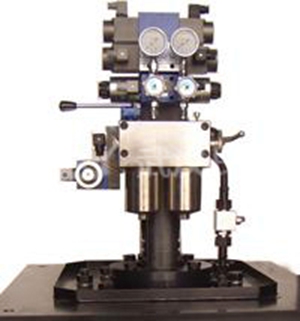

Governor of pumped storage turbine unit

.jpg)

.jpg)

The governor is provided with cross and full redundant system. TCP/IP network is adopted to ensure the communication between two computers. Its two programmable microcomputer regulators are provided with independent power supply. The stable working conditions of governor include: "stop and wait", "hydroturbine working condition (no-load)", "power generation working condition (load)", "phase modulation", "driver working condition", "water pump phase modulation (reverse no-load)", and "water pump working condition (reverse load). Wherein, the "hydroturbine working condition (no-load)" and "water pump phase modulation (reverse no-load)" are not optional. It means that they are necessary for entering other working conditions. Compared with the conventional hydroturbine unit, the reversible hydroturbine unit has a unique working condition-water pump steering (reverse).

Main characteristics

1. Control technology for electro-hydraulic proportional servo, which ensures high control accuracy and excellent governing performance;

2. Electric operation and manual operation are adopted to realize stable and reliable operation, and prevent the crawl of servomotor;

3. Unconditional and undisturbed switching between the automatic working condition and electric/manual working condition of electro-hydraulic proportional valve;

4. Hydraulic input and hydraulic feedback are adopted for auxiliary servomotor, which require no bar between electro-hydraulic conversion device and main distributing valve, and ensure simplified structure.

5. Except for the main distributing valve, all other parts are standard hydraulic parts, which are convenient for hydraulic integration and increase of working oil pressure.

Electrical cabinet

1. On-line test, and timely display of test parameters and graphics;

2. Self-adaptation of control structure; parameter adaptive regulating function; online expert system;

3. Frequency regulation function, power regulation function, and opening regulation function, which can be selected automatically according to different working conditions;

4. Regulating the guide vane opening according to the frequency variation speed of power grid;

5. LCD touch screen is provided with WINDOWS interface to realize test and fault recording;

6. Ensure the fast start, stop, grid connection, and increase/decrease of load for pump hydroturbine unit;

7. Ensure the pump hydroturbine unit to be operated under stable working conditions such as "stop and wait", "hydroturbine working condition (no-load)", "power generation working condition (load)", "phase modulation", "driver working condition", "water pump phase modulation (reverse no-load)", and "water pump working condition (reverse load).

8. Ensure the switching between manual operation and automatic operation without impulse;

9. Ensure the hydroturbine unit to automatically follow the system frequency as per the preset frequency difference under non-load working condition;

10. Ensure real-time correction of start opening, no-load opening, and restricted area for adverse working condition; automatic correction of dynamic sensitivity of speed governing system according to working condition, so as to adapt to the sensitivity requirements of different working conditions;

11. Ensure the real-time automatic compensation for mechanical zero drift, and; give corresponding instruction;

12. Limit the opening of electric device, and designate special operators for real-time adjustment;

13. Online real-time correction of artificial frequency dead band (ε) and difference coefficient (bp) is adopted to ensure no disturbance of load;

14. Ensure the local control and upper computer control, and; ensure no disturbance during the load control and switching;

15. Ensure the primary frequency control, so as to meet the requirements of power grid for the frequency modulation operation of hydroturbine unit;

16. Intelligent identification and control for the operation of small network and isolated network;

17. The control strategy with time-varying parameter is adopted to ensure timely identification of no-load, grid connection, isolated operation, and other working conditions with high reliability and stability;

18. Fluted disc or residual voltage is adopted for frequency measurement, so as to realize fast grid connection;

19. Friendly man-machine interface ensures convenient reading and modification of parameters;

20. Realize the communication with upper computer in line with certain communication protocol.

Patented technologies

1. Electro-hydraulic proportional follow-up unit for hydroturbine governor (Patent No.: 95 2 38033.1);

2. Hydraulic return to neutral position device for flow feedback in the position of main distributing valve (Patent No.: ZL 2008 2 0191121.9).

Main configuration

Electrical cabinet: PLC/PCC controller, color touch screen, and digital feedback;

Mechanical cabinet: electro-hydraulic proportional servo valve, and high-reliability main distributing valve.

For the main distributing valve, its nominal diameter is set at 100/150/200mm, and its working oil pressure is set at 6.3MPa.